Control Systems

TAD designs and builds control systems for mission-critical environments – bridges, manufacturies, vehicles, and beyond. We focus on reliability, safety and clarity of operation, combining robust hardware with well-structured firmware and intuitive Human-Machine Interfaces (HMIs) so operators can trust the system, not fight it. From multi-axis synchronisation to interlocks and fail-safes, we engineer for uptime and longevity.

Summary

On this page, you’ll see how we approach requirements capture, systems architecture, firmware and HMI development, and rigorous prototyping and validation. You can also explore real-world examples and understand how we move cleanly into manufacture, commissioning and lifetime support.

In industries where precision, reliability, and safety are paramount, well-engineered control systems can make all the difference. From large-scale hydraulics to complex refrigeration units, these systems serve as the operational backbone. At TAD, we design and develop both simple and complex solutions, depending on the needs of the client, that minimise downtime – key factors for any mission-critical project.

Why control systems matter

A reliable control system ensures that machines and processes operate within specified parameters, maintaining safety by detecting anomalies, triggering alarms, and even initiating shutdown procedures if conditions become hazardous. By tracking real-time data, these systems optimise performance, making instantaneous adjustments to preserve peak efficiency and limit human input error. Automated controls can react faster than manual interventions, reducing wear and tear on vital components. In essence, a well-crafted control system can be the difference between a smooth operation and a costly breakdown – particularly in applications like hydraulic rams, engine clutches, or multi-zone refrigeration.

Have a query or need to reach out?

Click here to get in touchOur approach to control system design

Analysis

We begin by immersing ourselves in your operational environment, mapping out everything from daily workflows to long-term maintenance goals. During this phase, we identify which metrics must be tracked in real time, explore how the system needs to integrate with existing protocols like CAN Bus or PLCs, and clarify any relevant safety or regulatory standards.

Systems architecture

Using insights from the ‘needs analysis’, we craft a comprehensive architecture that addresses hardware selection, communication protocols, redundancy measures, and future scalability. By balancing performance with cost efficiency, we help ensure your control system won’t become obsolete.

Software and firmware development

Embedded software drives every advanced control solution, especially when precision and response times are paramount. Our modular codebase supports real-time control loops, robust safety interlocks, and user-friendly HMIs that make monitoring more intuitive. Because it’s designed for flexibility, your system can evolve as new technologies emerge or requirements shift.

Prototyping and testing

Before finalising any design, we put each component – hardware and software – through a rigorous validation process. Our prototypes undergo tests for temperature extremes, vibration, and other real-world conditions. By iterating early and often, we catch potential pitfalls long before they escalate into costly failures.

Seamless manufacturing and deployment

With strong in-house manufacturing capabilities and supply chain partnerships, we transition swiftly from approved designs to production. Once installed, your control system can be monitored or updated remotely, ensuring it stays reliable throughout its operational life.

Real-world examples

Leamouth Bridge

One of our flagship projects involved designing and manufacturing control cabinets to synchronously lift four hydraulic rams on a pedestrian bridge in London. With thousands of residents relying on the bridge for daily transit, safety and reliability were paramount. Our solution continuously monitored system interlocks and error conditions, requiring dual-operator oversight on either side of the bridge to enhance operational security. Multiple redundancy layers within both the hydraulic and electronic systems helped minimise the risk of catastrophic failure.

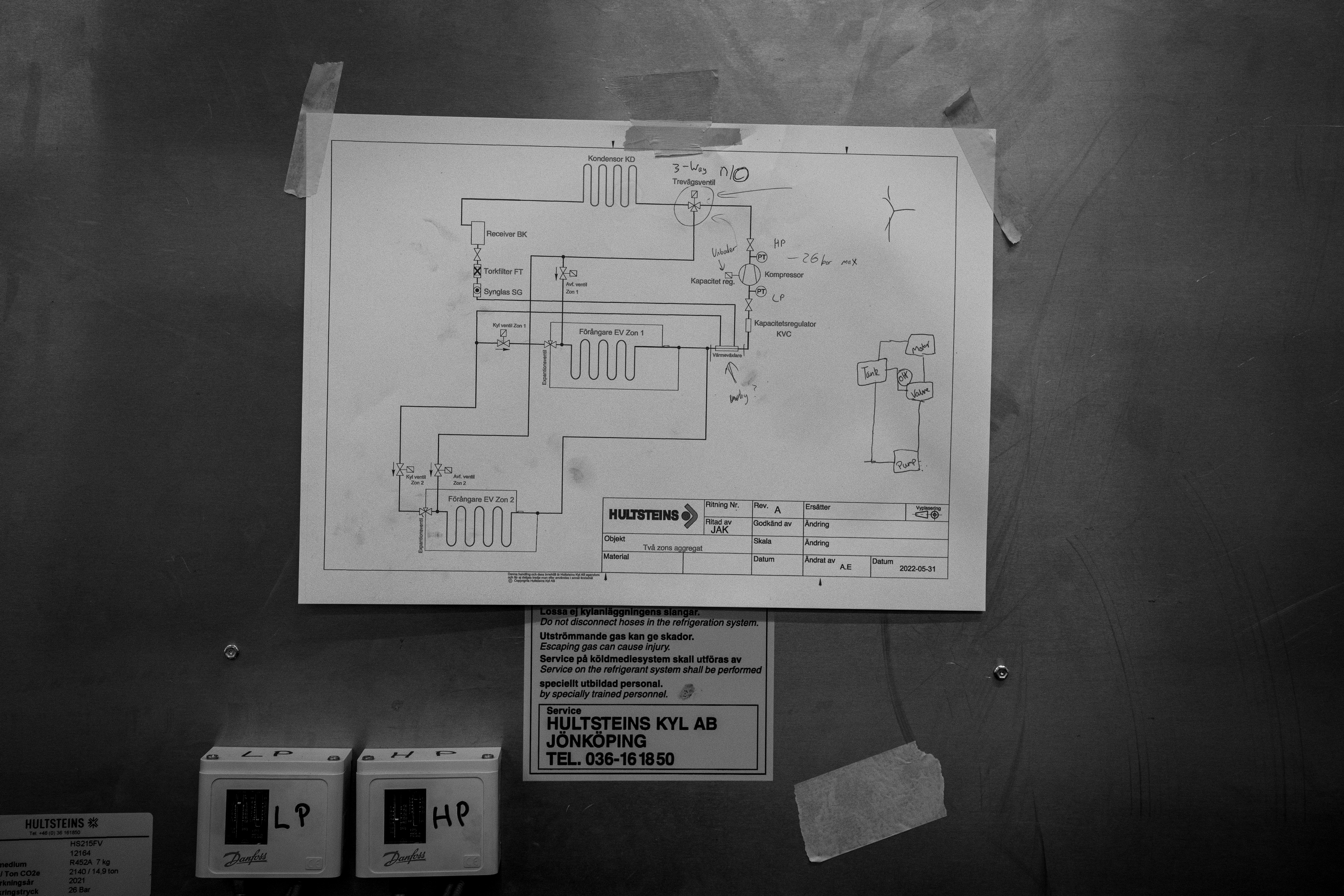

Hultsteins Refrigerated Lorries

In the logistics world, precise temperature control can significantly impact the supply chain. For Hultsteins, we developed a modular control system for multi-zone refrigeration, featuring a user-friendly HMI for quick adjustments, remote access for offsite troubleshooting, and CAN Bus integrations that harmonised with the vehicle’s existing communication network. This design helped reduce the likelihood of spoilage while maximising overall efficiency.

Case Studies

Key features and capabilities

- High reliability – Our systems are engineered for challenging environments, from mobile applications to outdoor installations.

- Custom PCB design – We optimise hardware for your project’s unique demands, streamlining complexity.

- Safety-critical software – We use proven development practices to enable rapid fault detection and safe shutdown procedures.

- Obsolescence avoidance – By choosing component families with stable lifecycles, we reduce the risk of sudden part discontinuations.

- Scalability – Our architectures can grow with your requirements, scaling from a single sensor node to a large, integrated facility.

How we work

Our engagement typically begins with a thorough consultation to understand your project’s requirements and constraints in detail. We then propose an initial system architecture, inviting your feedback and refining it to ensure alignment with your operational goals. Once the conceptual design is agreed upon, we move quickly into prototyping, where we transform ideas into functional demos for practical evaluation. This iterative cycle of testing and refinement allows us to integrate your insights and address potential issues before they affect production schedules.

When the design has been fully validated, we shift to production and deployment. Whether you need a short production run or full-scale manufacturing, our facilities and partnerships accommodate a wide range of volumes. For on-site installations, we coordinate logistics to keep disruptions to a minimum. Even after deployment, our commitment continues through our Lifetime Support [link] service, which helps maintain your control system’s performance with regular check-ups, firmware updates, and hardware refurbishments.

Ready to take control?

Control systems lie at the heart of many groundbreaking projects – from hydraulically powered drawbridges to complex refrigeration processes. At TAD Electronics, we’re eager to explore how a customised, durable control system can enhance efficiency, ensure safety, and bolster long-term value in your operations.

If you’re considering a new project or looking to upgrade an existing control setup, get in touch to discover how our expert design and manufacturing capabilities can deliver a solution that’s both cutting-edge and future-proof.